What is titanium seamless pipe ?

Titanium seamless pipes are a type of piping made from titanium that does not have any welded joints. titanium pipe and tube are manufactured through a seamless process, which involves extruding a solid billet of titanium through a die to create the pipe shape without any seams.it has a broad of applications includes titanium round pipe,titanium rectangle pipe,titanium capillary tube,seamless titanium tube etc.

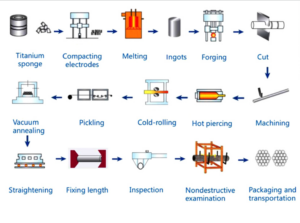

The production process of seamless titanium pipe

Forging rod—-cutting—-peeling—-heating—-flat head—-drilling—-boring—-wrapping—-heating—-squeezing Pressing—-straightening—-head cutting. Interruption—-pickling—-inspection and repair—-cold rolling—-degreasing—-pickling—-vacuum Annealing—-straightening—-sampling—-finishing—-inspection—-packaging—-warehousing.

The advantage of seamless titanium pipe

1. **Corrosion Resistance**: Titanium piping is known for its exceptional resistance to corrosion, making seamless titanium pipes suitable for various challenging environments, including those with high levels of acidity or salt.

2. **High Strength-to-Weight Ratio**: Titanium seamless pipes are lightweight yet strong, making them ideal for applications where weight is a importance, such as in aerospace or marine industries.GR1,GR2,GR3,GR5 ASTM A348 Specifications

3. **Heat Resistance**: Titanium can withstand high temperatures, making titanium seamless pipes suitable for applications involving elevated temperatures.such as chemical processing industry.CP1,CP2,CP3,CP4 (Commercial Pure Titanium)

4. **Biocompatibility**: Titanium tubing is biocompatible, which makes seamless titanium tubes suitable for medical applications, such as in implants and surgical instruments.such as titanium alloy Grade 5-ELI titanium tubes.

The applications of titanium tubes

Titanium tubes find applications in a wide range of industries and fields due to their unique properties. Some common applications of titanium seamless tubes include:

1. **Aerospace**: Titanium tubes are used in aircraft structures, hydraulic systems, and engine components due to their high strength-to-weight ratio and resistance to corrosion at high altitudes.

2. **Industrial**: Titanium piping are utilized in heat exchangers, condensers, and piping systems in chemical processing, desalination plants, and power generation facilities due to their excellent corrosion resistance.

3. **Medical**: Titanium tubing are used in medical devices, such as implants, surgical instruments, and dental applications, due to their biocompatibility and resistance to bodily fluids.

4. **Oil and Gas**: They find applications in offshore drilling rigs, subsea equipment, and pipelines due to their corrosion resistance in harsh marine environments and high strength.

5. **Sporting Goods**: Titanium seamless tubes are used in the manufacturing of high-performance bicycle frames, golf club shafts, and other sporting equipment due to their lightweight and durable nature.

6. **Automotive**: They are used in exhaust systems, suspension components, and other parts where corrosion resistance and weight reduction are important.such as titanium exhaust pipes.

7. **Marine**: Titanium tubes are used in shipbuilding, desalination plants, and offshore structures due to their resistance to corrosion in seawater.

These applications highlight the versatility and usefulness of titanium seamless pipe across various industries.