What is titanium mill products and titanium round bars?

Titanium mill products refer to the range of semi-finished titanium materials, produced by milling, such as titanium round bars, titanium alloy rods, sheets, plates, titanium tubes, and other forms. These products are commonly used as raw materials in various industries, including aerospace, medical, automotive, and marine engineering. Titanium mill products are valued for their high strength-to-weight ratio, corrosion resistance, and biocompatibility, making them suitable for a wide range of applications.

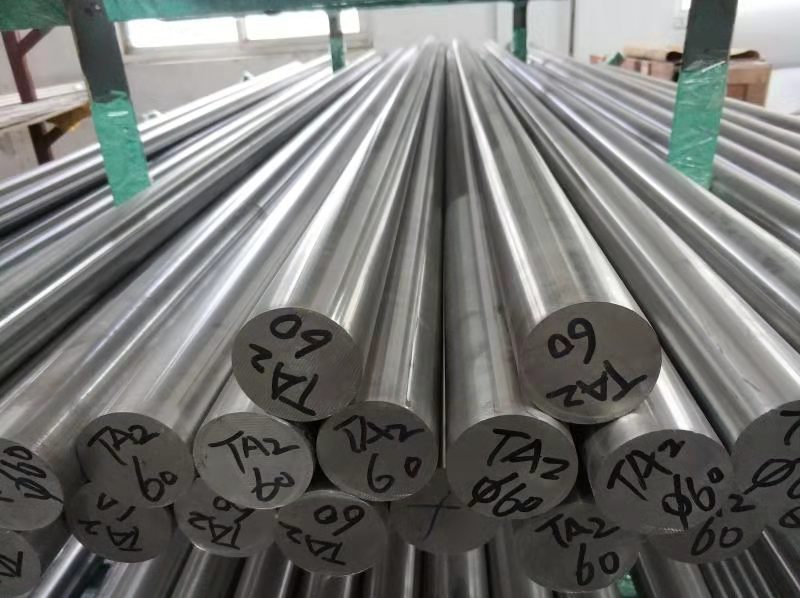

- Product name: GR5 titanium alloy rods,titanium round bars

- Grade:National standard: TA1, TA2, TA3, TA9, TA10, TC4, TA18, ERTI-1, ERTI-2, Ti15333 American standard: GR1, GR2, GR3, GR5, GR7, GR12,

- Manufacturing process: Hot forging + turning (grinding)

- Delivery status: R (hot working status) M (annealed status)

- Diameter (mm) Ø1.0-Ø200

- Implementation standards: GB/T 2965, GB/T13810, ASTM B348, ASTM F136, ASTM F67, AMS 4928 6,

- Characteristics: Titanium alloy rods have high strength, good corrosion resistance, good low-temperature performance, chemical activity, thermal conductivity and elasticity. Excellent performance.

- Applications: (1) Chemical industry: Titanium alloy rods are mainly used in chlor-alkali industry, electroplating industry metal anode electrolyzer, ionic membrane electrolyzer, filters, pumps and valves, wet oxygen cooler, refined brine preheater, dechlorination tower, chlorine cooling and scrubbing tower, and so on. (2) Medical field: TC4 titanium rods are mainly used as medical devices, orthopedic implants, such as bone splints, joints and spine. (3) Petroleum field: TC4, TC11, TC18 and other high-strength titanium alloy rods are drilled and machined into titanium alloy tubes, which are mainly used for the outer barrel of petroleum logging instruments, the outer barrel of inclinometers, as well as deep-sea pressure-resistant silos and other products. (4) Aerospace field: aircraft nozzle, fuselage frame, impeller and other parts.

The production process of titanium round bars

1. **Melting**: Titanium sponge or scrap is melted in a vacuum or inert atmosphere to prevent contamination.

2. **Casting**: The molten titanium is then cast into an ingot using various methods, such as vacuum arc remelting (VAR) or electron beam cold hearth melting (EBCHM).

3. **Hot Working**: The cast ingot is then heated and hot worked into a billet or slab through processes:like forging or extrusion to achieve the desired shape and size.

4. **Heat Treatment**: The titanium billet may undergo heat treatment to improve its mechanical properties and remove residual stresses.

5. **Cold Working**: The billet is further processed through cold working techniques, like rolling or drawing to achieve the final dimensions and surface finish.

6. **Cutting**: The processed titanium billet is cut into individual bars of specific lengths.

7. **Quality Control**: Throughout the entire process, quality control measures are implemented to ensure the titanium round bars meet the required specifications and standards.

8. **Finishing**: The titanium round bars may undergo additional processes such as straightening, surface treatment, or inspection before being ready for distribution or further machining.

These steps may vary slightly depending on the specific requirements and the intended application of the titanium round bars .