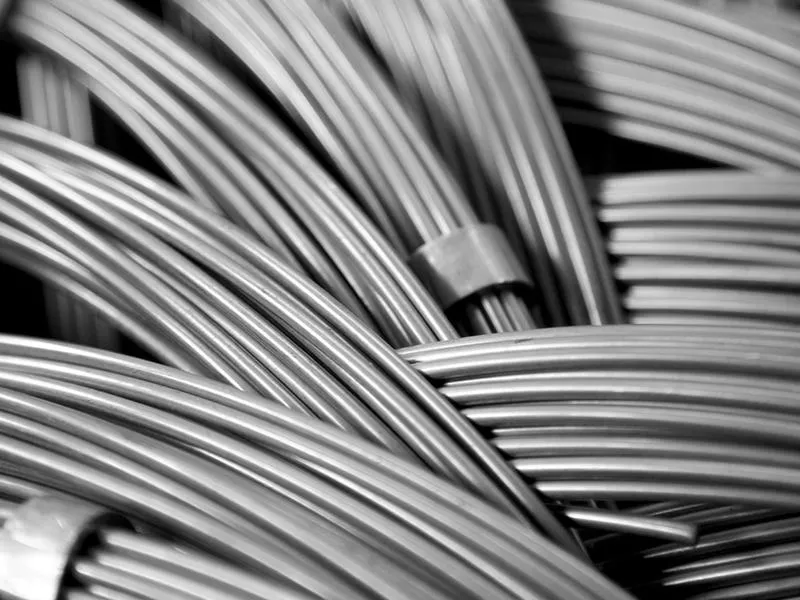

Titanium and titanium alloy wires are widely used in many fields such as aerospace, petrochemical industry, medical and health care, automobiles, construction, sports and leisure products. In recent years, due to its continuous development, there are more and more varieties, which provides more choices for its high-performance industrial supplies and consumer product applications.

At present, more than 80% of titanium and titanium alloy welding wires are used as welding wires, such as the welding of various titanium equipment, welded pipes, aviation jet engine turbine plates, repair welding of blades, and casing welding, etc.

Titanium wire is widely used in chemical, pharmaceutical, papermaking and other industries because of its excellent corrosion resistance. It has developed into networks such as seawater filters, pure water filters, and chemical filters.

Titanium and titanium alloy wire have good comprehensive properties and can be used to manufacture fasteners, load-bearing components, springs, etc.

In the medical and health industry, titanium and titanium alloy wires are widely used in medical devices, dental implant crowns, skull fixation and other fields due to their excellent biocompatibility.

Some titanium alloys with shape memory function, such as nickel-titanium alloys, are used to manufacture satellite antennas, clothing shoulder pads, women’s bras and eyeglass frames.

Titanium and titanium alloy wires are used in the electroplating and water treatment industries to manufacture various electrodes.

Specification of titanium wire:

A. Titanium wire specifications: φ0.8-φ6.0mm

B. Specification of titanium wire for eyeglasses: φ1.0-φ6.0mm special titanium wire.

C. Specification of titanium wire: φ0.2-φ8.0mm special for hooks.

Grade of titanium wire:

GR1/GR2/GR3/GR4/TC4 etc.