According to relevant news, mainstream 3C manufacturers such as Honor, Apple, and Samsung have begun to introduce titanium alloy materials to varying degrees. Titanium alloys are accelerating their penetration into consumer electronics such as mobile phones, smart wearables, tablet computers, and notebook computers. The growth space of the titanium alloy industry is expected to continue to open up.

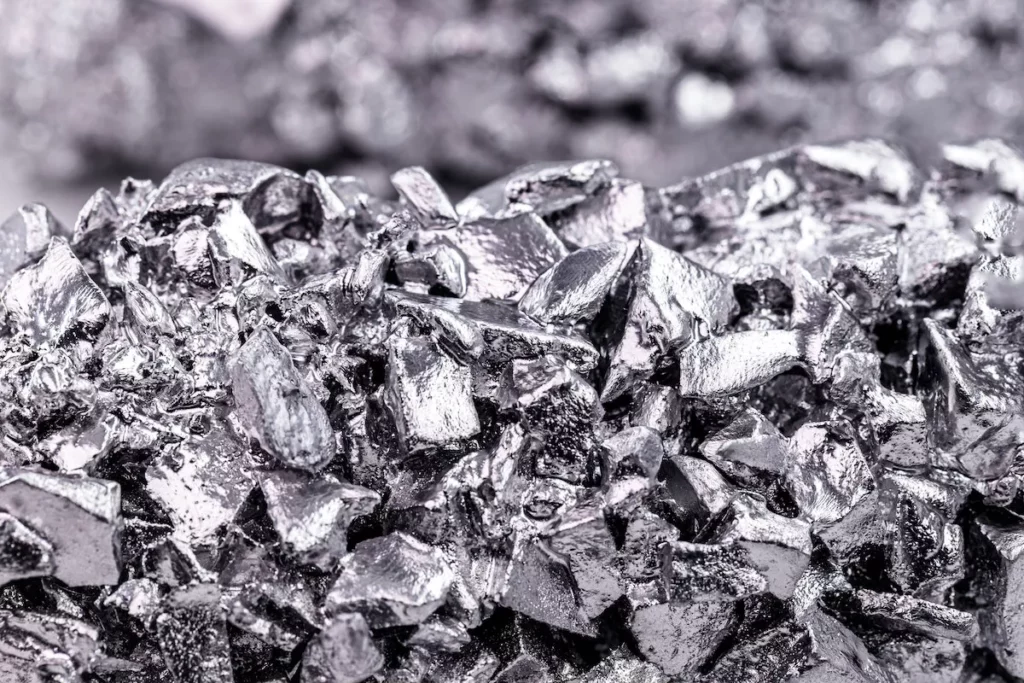

Compared with traditional stainless steel, aluminum alloy and other materials, titanium metal can better balance the hardness and weight of parts. It can be both light and hard, and can better meet the thinning and lightness requirements of 3C products.

At present, titanium alloy processing technology mainly includes CNC cutting and grinding and 3D metal printing. Due to the material characteristics of titanium alloy, the processing links (forming, grinding and polishing) compared with aluminum alloy, the use of cutting and grinding to process titanium alloy products has difficulties such as low yield, long time consumption, and large demand for equipment. Taking the middle frame of a mobile phone as an example, according to According to Aibang Polymer data, the overall yield rate of titanium alloy mobile phone middle frames is about 30%-40%, which is much lower than the 80% of aluminum alloy middle frames; and the processing time is long, about 3-4 times that of aluminum alloy. As a A new direction in titanium alloy processing, metal 3D printing is rapidly manufactured based on the three-dimensional model of the part. It does not require special molds, uses powdered metal materials, and uses a layer-by-layer printing method to construct objects. It has the characteristics of high convenience, high precision, and low cost. In addition, in the field of titanium alloys, hot isostatic pressing can effectively improve the mechanical properties of titanium alloy workpieces, reduce the cost of titanium alloys, and improve production efficiency and material utilization.

It is worth noting that metal 3D printing also needs to be combined with the grinding and polishing process of CNC machine tools. Since 3D printed parts usually have rough surfaces, additional post-processing such as machining, grinding or polishing is required to obtain a smooth surface with high precision. Due to the material characteristics of titanium alloy, the processing links (forming, grinding and polishing) are of higher value and the consumption of processing consumables is greater. 3D printing is one of the ways to form titanium alloys and has begun to be industrialized on a large scale. The value of subsequent grinding and polishing (finishing processes) is expected to increase significantly.

Companies such as Changying Precision, Platinum, and Golden Sun have made it clear that they are involved in titanium alloy 3D printing technology. Changying Precision disclosed in its 2023 semi-annual report that titanium alloy will become a new choice for consumer electronics customers due to its high hardness and strong antibacterial properties. The company is cooperating with major customers to implement the full process technology of titanium alloy materials, laying the foundation for the follow-up The project is ready for mass production.